Product Description

2141 Auto Tool Changing Woodworking Furniture CNC Machine with Aluminum Table

Application

Woodworking products, advertising signs, MDF board, cutting engraving Photo frame, sculpture the sofa and the head of a bed, All kinds of wood door carvings, Large furniture relief engraving, Dalle hollow out and simple copper aluminum plastic board, etc

Features

1.Whole machine is welded by strong steel structure, with tempering aging treatment, no distortion, long time using.

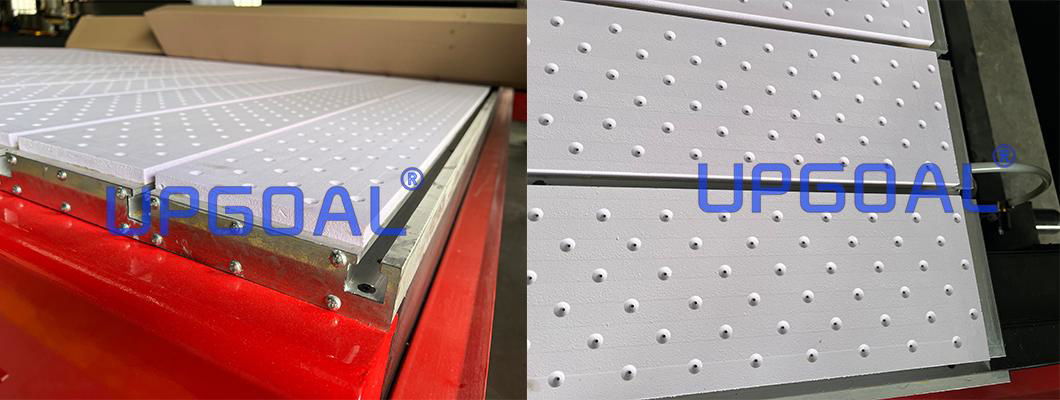

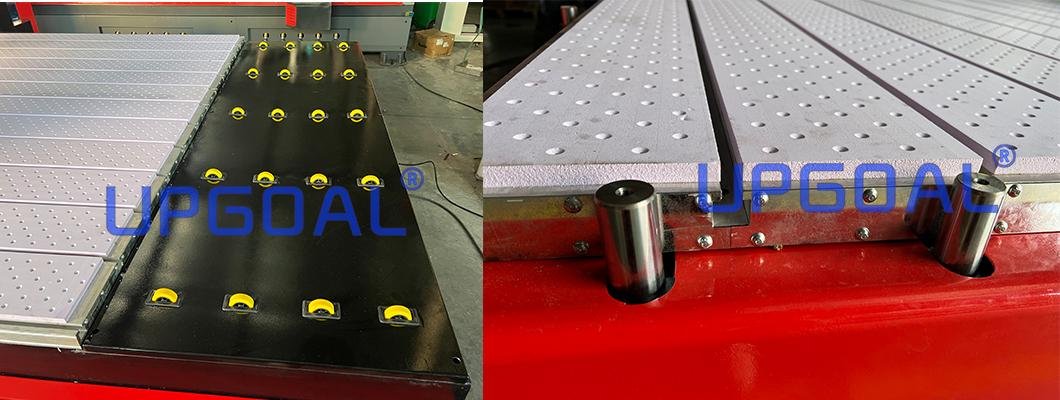

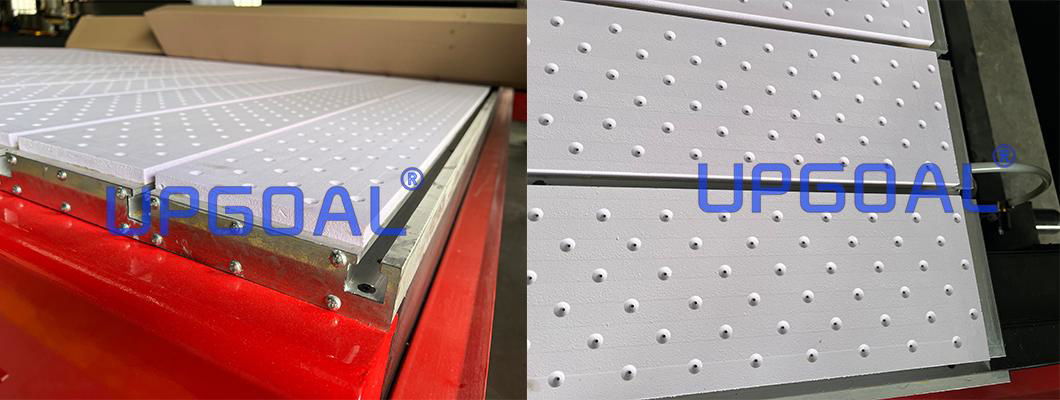

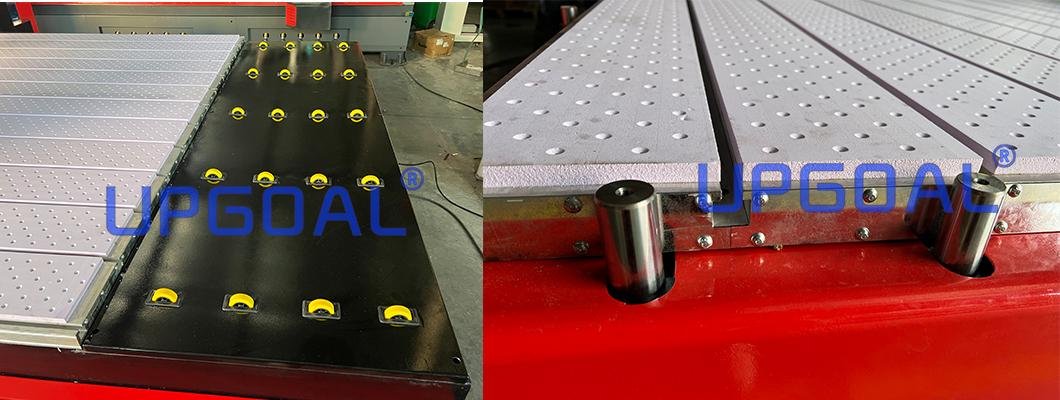

2. Vacuum adsorption system: customized Europe technology cast aluminum vacuum adsorption table with aluminum alloy T slot & pilot pin & feeding wheels , adopted bakelite table, high density, no deformation and high adsorption, can for different size materials adsorption, saving time compared the traditional mechanical plate fixing, the vacuum pump is 3 sets 7.5kw air cooling type to solve water cooling vacuum pump changing water issue in the frigid weather.With feeding wheels on the back of machine, convenient for heavy materials loading.

3. Disc type auto tool changer system, total 8 pcs(or more) bits in the tool magazine, only 8 seconds to change bits, can change the needed bits intelligently, saving bits changing time, improving efficiency.

4.Adopted with famous China HQD 9.0KW ATC air cooling spindle, high precision, low noise, high RPM, long life time , and stable moving.

5.Famouns Delta brand 11KW inverter, for spindle muti-speed adjusting.

6.The latest SYNTEC Taiwan 60CB high performance industrial control system, intelligent controlling, has the protection function for beyond the working table, avoiding the mechanical collision due to the larger designed layout. Intelligent control the speed, can control the processing speed severally, truly improve the processing efficiency and lengthen the tools life time, increase the rate of finished products. Can do multi layer 3D processing, fast and smooth do three-dimensional processing, engraving and cutting.

7. Powerful SYNTEC 1000W servo motor and driver for XYZ-axis, suitable all kinds of heavy solid wood engraving and cutting, high precision and fast speed.

8.Advanced bus control method for numerical control and motion control, when turn on the machine, then can work directly no need do set the O point every time, higher reliability , stronger the anti-interference ability is stronger, and no pulse loss.

9. Japan Shimpo reducer for servo motor, used for replace traditional rack and belt,to make machine more powerful and stable.

10. Linear square guide rail, Hiwin, Taiwan, dia 30mm for XYZ-axis, double raw four columns, good weight capacity, stable moving and ensuring the precision. Germany WHM Heilon helical gears pinion and rack transmission for X and Y axis, higher running speed and efficiency, saving cost. Z- axis with precision ball screw, high precision and more durable.

11. Double bags dust collector helps to suck the dust, milling dust, saw dust during processing, keeping the working table cleaning and ensuring the machine long time using.

12. With oil mist cooling device when processing alumimum/metal work pirece, impproving engraving cutting precision.

13. Indpendent SYNTEC control cabinet with famous brand electronic parts.

14.Precisioin auto tool calibration, more convenient for each time Z-axis 0 point setting.

15.Auto lubrication system more convenient for maintenance.

16.Advanced file processing function, can timely correct faults, and good compatibility forType3/Artcam/Mastercam/Caxa such file. Advanced three dimensional curve forcast algorithm, stable broken line, ensuring the curve moving speed & precision.

17. Memory function after power failure and break point, can auto back to zero point and correct the faults, ensuring the precision for long time working and saving materials.

Technical Parameters

|

Effective working area

|

2100(X)mm*4100(Y)mm*300(Z)mm

|

|

Materials

|

Strong square steel pipe welded structure for whole machine

|

|

Working table

|

Cast aluminum vacuum table with aluminum alloy T slot

|

|

Moving type

|

Gantry moving

|

|

Guide rail

|

Linear square guide rail ( Hiwin, Taiwan, dia 30mm)

|

|

Transmission

|

WHM helion helical rack &pinion for X Y -axis, Lead ball screw for Z-axis

|

|

Driving mode

|

SYNTEC Taiwan 1000W servo motor and driver for XYZ-axis

|

|

Spindle motor

|

9.0KW China HQD ATC air cooling spindle(ISO30)

|

|

Spindle speed

|

12000-24000rpm

|

|

Tools changing method& changing ability

|

Disc auto tool changer, 8 pcs

|

|

Inverter

|

Delta,11KW

|

|

Voltage

|

AC 380V/220V± 10%, 50/60Hz, three phases

|

|

Maximum traveling speed

|

60000-800000mm/min

|

|

Maximum engraving speed

|

25000-40000mm/min

|

|

Machine accuracy

|

0.01mm

|

|

Control system

|

SYNTEC 60CB control system( 4 axis)

|

|

Hand wheel

|

SYNTEC HPG( hand pulse generator)

|

|

Suitable software

|

Artcam, Type3, Ucancam V9,etc

|

|

Carving Instructions

|

G code *Uoo *mmg *plt HPGL

|

|

Running environment temperature

|

0-45 ºC

|

|

Relative humidity

|

30%-75%

|

|

Dedusting device

|

Dust collector, 7.5kw

|

|

Oil mist cooling system

|

With

|

|

Lubrication system

|

Automatic

|

|

Tool calibration

|

Auto

|

|

Certificate

|

CE

|

Reference Working Videos

https://youtu.be/eurkXCYOwYI?si=G3jkp1FDeYlawMZU

https://youtu.be/IDU6UpyGKA8?si=9v9Ch9hQHDSU4My3

For more information, just feel free to contact us!

Jinan Upgoal Mechanical Equipment Co.,Ltd

CNC Router/Laser Engraving Cutting Marking Welding Cleaning Machine/Plasma Cutting Machine

Payment Terms︰

T/T, L/C,Western Union...

Product Image