Product Description

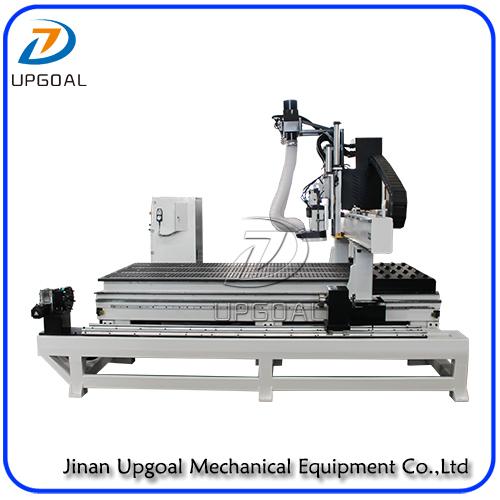

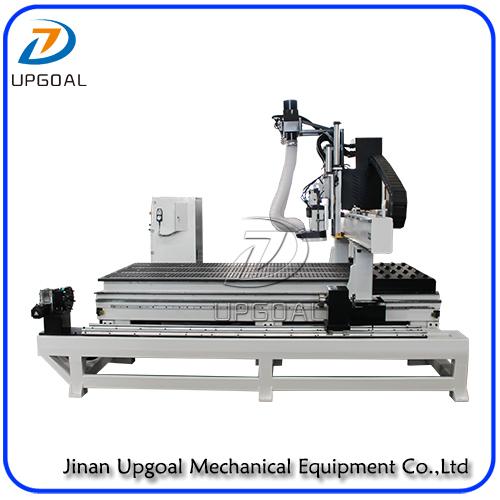

4 Axis Three Spindles Changing ATC CNC Engraving Cutting Machine 1300*2500mm

Application

Woodworking industry: three-dimensional waved plate, cabinet door, craft door, overlaid wood composite door, screen, solid wood door, craft casement window, etc, such furniture product milling and engraving, also for shoe-cleaning machine, game machine cabinet and panel, mahjong table, computer table and auxiliary processing of panel furniture,mainly used for cabinet door, solid wood furniture, also can for MDF cutting & processing.

Features

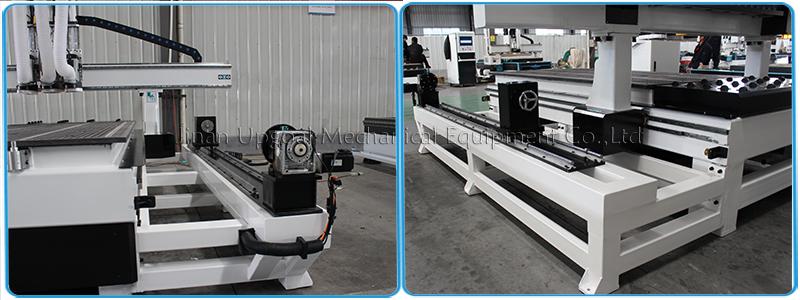

1. Strong welded steel T type structure as a whole with vibration Temper aging treatment ensures no deformation for long time.Cast iron Gantry, the structure is strong and stable.

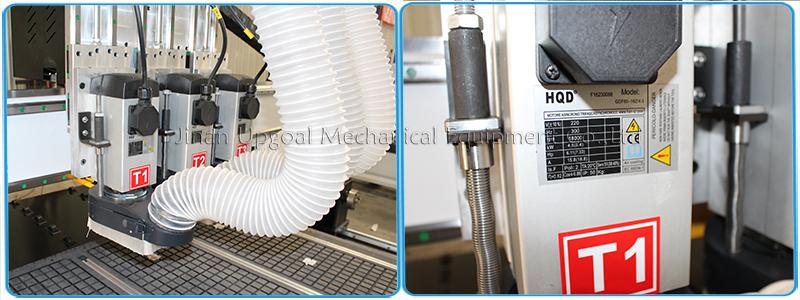

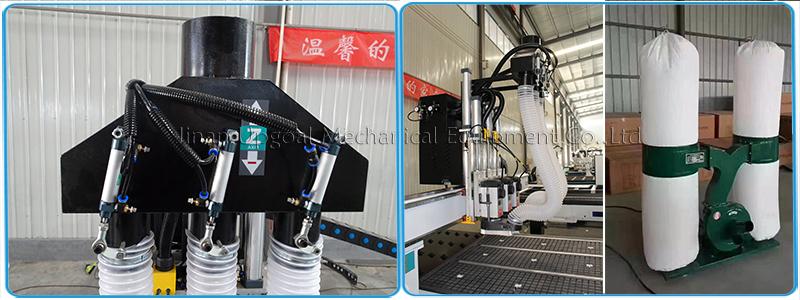

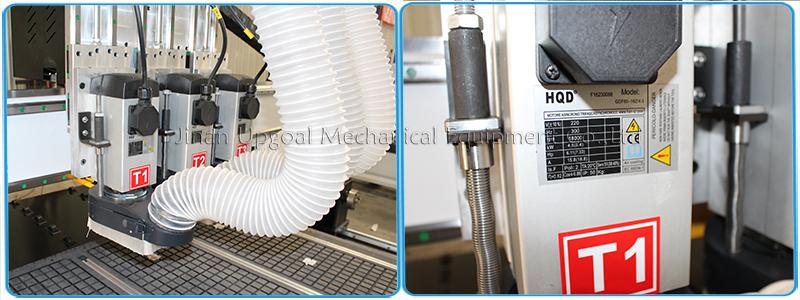

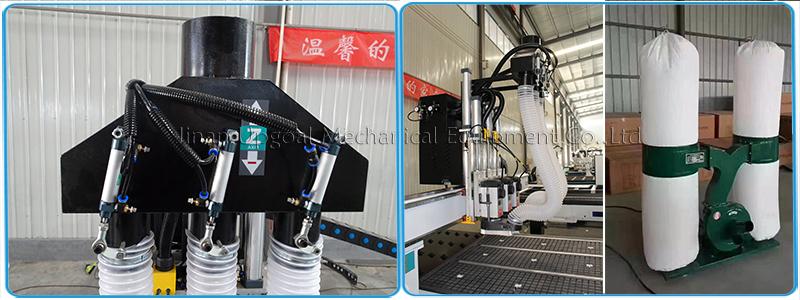

2. Three spindles air cylinder ATC cnc router is multi-spindles asynchronous operating cnc router, with 3 spindles alternatively working, can realize the tools changing quickly, saving the time of manual changing tools, improving the processing efficiency and precision. Three spindles can be used arbitrarily, 3 spindle tools for 3 kinds of pattern engraving by turns, has the function of 3 pcs tools auto changing function, Compare the linear or disc ATC cnc router, which cost is much cheaper.

3. Large power China HQD 4.5KW air cooling spindle of three, which is with stable performance and high torque, matched with high-performance frequency inverter.

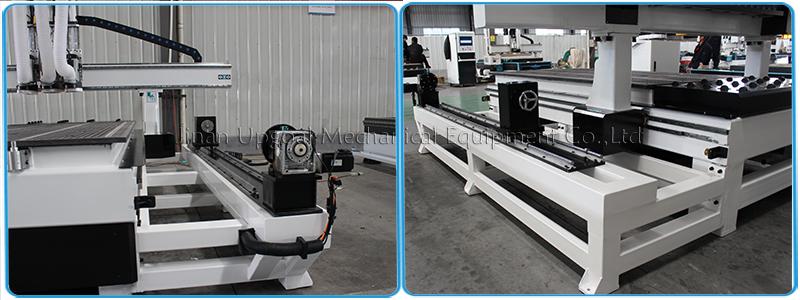

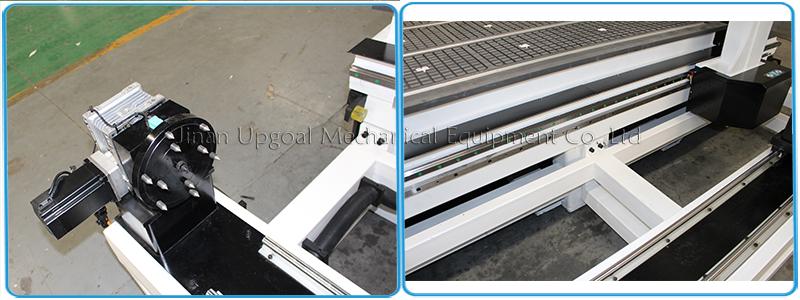

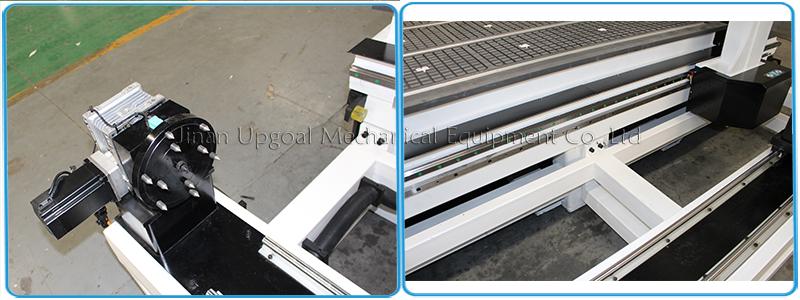

4. Extended gantry & independent removable rotary axis holder, with diameter 500mm, working length 2500mm, cylinder processing is in a special zone, each time, no need put the heavy rotary axis on the working table, saving labor and improving working efficiency.

5. Imported Hiwin, Taiwan Linear square guide rail (diameter 25mm) with ball bearing slide block which ensure high weight capacity, high precision, smooth and steady running. Adopt imported precision ball screws, tools feeded with more accuracy.Precision XINYUE helical gears pinion and rack transmission for X and Y axis, higher running speed and efficiency. Z- axis with precision ball screw, high precision and more durable.

6. Adopted Leadshine hybrid servo motor(86HSM) and driver(H2-2206) for XYZA-axis, high precision, fast speed and more stable, dual motor driven Y axis with traveling speed up to more than 25000mm/min.

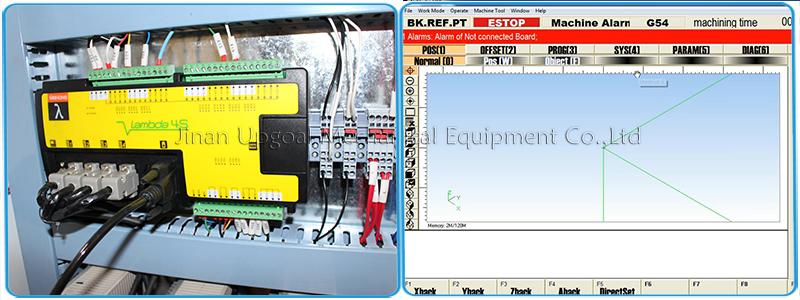

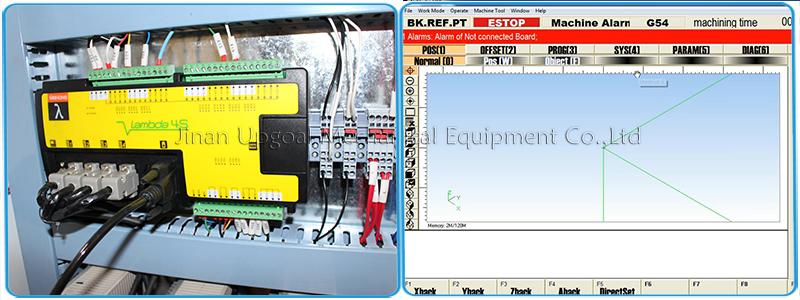

7. Weihong Original NcStudio V8 control system supports air cylinder automatic tools changer, with high precision, low noise, showing the processing path, memory function after break point and power failure.

8. Vacuum adsorption system with 5.5kw air cooling vacuum pump, vacuum table which is divided into 6 zones,can adsorb different size materiel from small to big, saving materials load-unloaded time.

9. Dust collector (3.0kw double bags)helps to suck the dust, milling dust, saw dust during processing, keeping the working table cleaning and ensuring the machine long time using.

10. With feeding wheels on the back of machine, convenient for heavy materials loading.

11. Precisioin auto tool calibration, more convenient for each time Z-axis 0 point setting

Technical parameters

|

Effective working area

|

1300(X)mm*2500(Y)mm*300(Z)mm

|

|

4th axis rotary axis

|

Independent removable diameter 500mm, length 2500mm, reduction gear transmission

|

|

Materials

|

Strong welded steel pipe welded structure

|

|

Working table

|

Vacuum table with aluminum alloy T slot working table

|

|

Moving type

|

Gantry moving

|

|

Guide rail

|

Linear square guide rail ( Hiwin, Taiwan, dia 25mm)

|

|

Transmission

|

XINYUE Helical rack &pinion for X Y -axis,

Lead ball screw for Z-axis

|

|

Driving mode

|

China Leadshine hybrid servo motor(86HSM) and

driver (H2-2206)for XYZA-axis

|

|

Spindle motor

|

4.5KW*3 air cooling( HQD, China)

|

|

Spindle speed

|

0-18000rpm

|

|

Tools changing method

& changing ability

|

Air cylinder pneumatic ATC, 3 pcs

|

|

Inverter

|

Delta

|

|

Voltage

|

AC 380/220V±10%, 50/60Hz, three phases

|

|

Maximum traveling speed

|

60000-800000mm/min

|

|

Maximum engraving speed

|

25000-40000mm/min

|

|

Machine accuracy

|

0.01mm

|

|

Control system

|

Weihong NcStudio V10 for air cylinder ATC(4 axis version)

|

|

Suitable software

|

Artcam, Type3, Ucancam V9,etc

|

|

Carving Instructions

|

G code *Uoo *mmg *plt HPGL

|

|

Running environment temperature

|

0-45 ℃

|

|

Relative humidity

|

30%-75%

|

|

Vacuum pump

|

5.5kw air cooling

|

|

Dedusting device

|

Dust collector, 5.5kw

|

|

Lubrication system

|

Auto

|

|

Tool calibration

|

Auto

|

|

Certificate

|

CE

|

Reference Working Videos

https://www.youtube.com/watch?v=4wl5LgZL5m8

For more information, just feel free to contact us!

Jinan Upgoal Mechanical Equipment Co.,Ltd

CNC Router/Laser Engraving Cutting Marking Machine/Plasma Cutting Machine

Payment Terms︰

T/T, L/C, Western Union, MoneyGram...

Product Image